Holiday notice: our laboratory will be closed from Thursday, 25th December. All operations will resume as normal from Monday, 5th January 2026.

We have a range of in-house materials analysis services that can be used for stand alone results or as part of a wider investigation. Our comprehensive range of techniques include: SEM-EDS, Spark OES, FTIR, XRF, GCMS, and HPLC.

Name: (SEM-EDS) Energy Dispersive Spectroscopy

Instrument: Oxford Instruments Xplore 30

SEM EDS combines the high resolution imaging of the scanning electron microscope with elemental analysis. EDS works by measuring X-rays generated by the interaction between the electron beam and the area of the sample being viewed. Each element has a specific energy allowing for the determination of the elements present. The EDS function can conduct analysis of particles, coatings, metallurgical phases etc at high and low magnifications to give a breakdown of the elements present. Its range of functions include: area and spot analysis, line scanning and mapping.

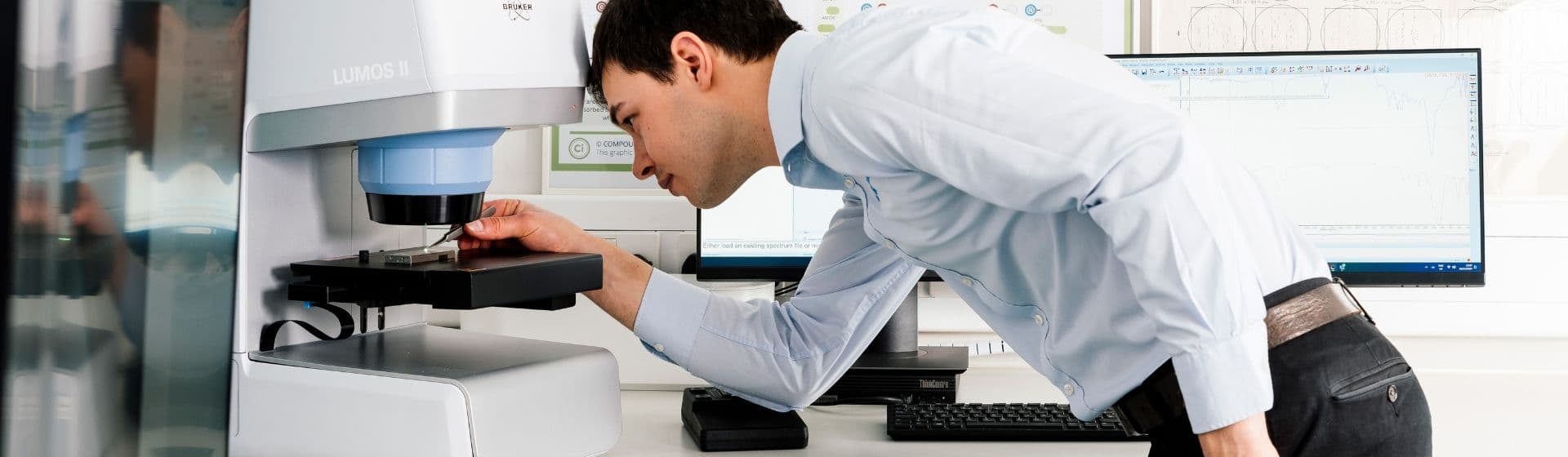

Name: (Spark OES) Optical Emission Spectroscopy

Instrument: Arun Technology Artus 8 Ultimate

OES is the industry standard technique for analysis of metal alloys. A high-energy spark vaporizes a tiny portion of the metal sample, turning it into plasma. The excited atoms in the plasma emit light, which is captured and analysed based on its wavelength. Each element emits light at specific wavelengths, allowing the system to identify and quantify the elements present in the sample. We are able to conduct Spark OES on high and low carbon steels, stainless steels, aluminium alloys and copper alloys.

Name: (FTIR) Fourier Transform Infrared Spectroscopy

Instrument: Shimadzu IR Tracer 100

FTIR is a spectroscopic technique which can be used for qualitative and quantitative analysis of solids, liquids and gases. IR spectroscopy measures the interaction of IR radiation with a sample to provide chemical identification. The spectrometer measures the energy (wavenumbers) required to incite molecular vibrations. The different functional groups of the molecules vibrate at different specific energies which are presented as unique bands within the resulting infrared spectrum. This spectrum is then a unique infrared 'fingerprint' specific to the sample which can be cross-referenced to allow for identification. We utilise FTIR as part of failure investigations, contaminant/debris analysis and material identification/verification. The technique can be used to analyse a variety of samples including polymeric materials, textiles and liquids (such as oils and coolants).

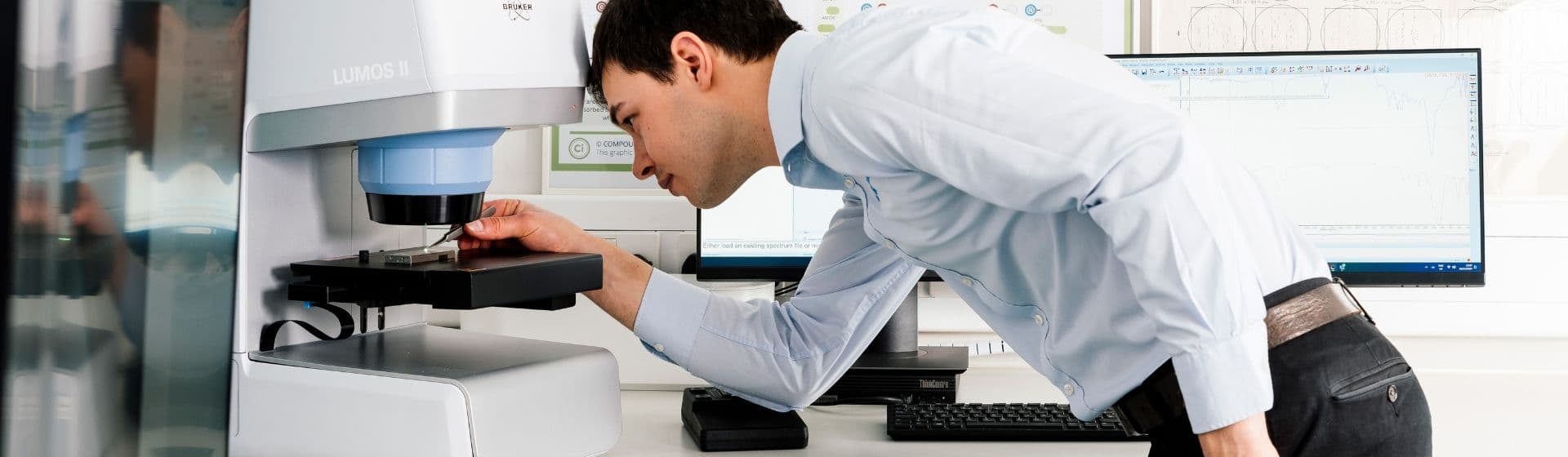

Name: (Micro FTIR) Fourier Transform Infrared Spectroscopy

Instrument: Bruker Lumos 2

Microscope-FTIR Spectroscopy is a more specific infrared spectroscopy application. The technique uses the same principles as traditional FTIR spectroscopy but utilises microscope imaging to allow for more specific, targeted analysis. Samples and/or areas of interest are examined and identified using an optical microscopy system and then chemically characterised using infrared spectroscopy. Our Microscope-FTIR can be used for: chemical imaging whereby variations in chemical characteristics can be overlaid on top of a visual image and analysis of microscopic particles and fibres down to an approximate size of 5 microns. These features allow SureScreen Materials to utilise Microscope-FTIR as part of failure investigations, contaminant/debris analysis and material identification/verification but typically in a more targeted manner than traditional FTIR.

Name: (XRF) X-Ray Fluorescence

Instrument: Bruker S1 Titan

XRF enables rapid, non-destructive identification and quantification of elements in various samples, from metals to minerals and coatings. This can be done both in the laboratory or onsite. The technique is used for identifying metal alloy grades, restricted materials and for testing in accordance with ROHS requirements.

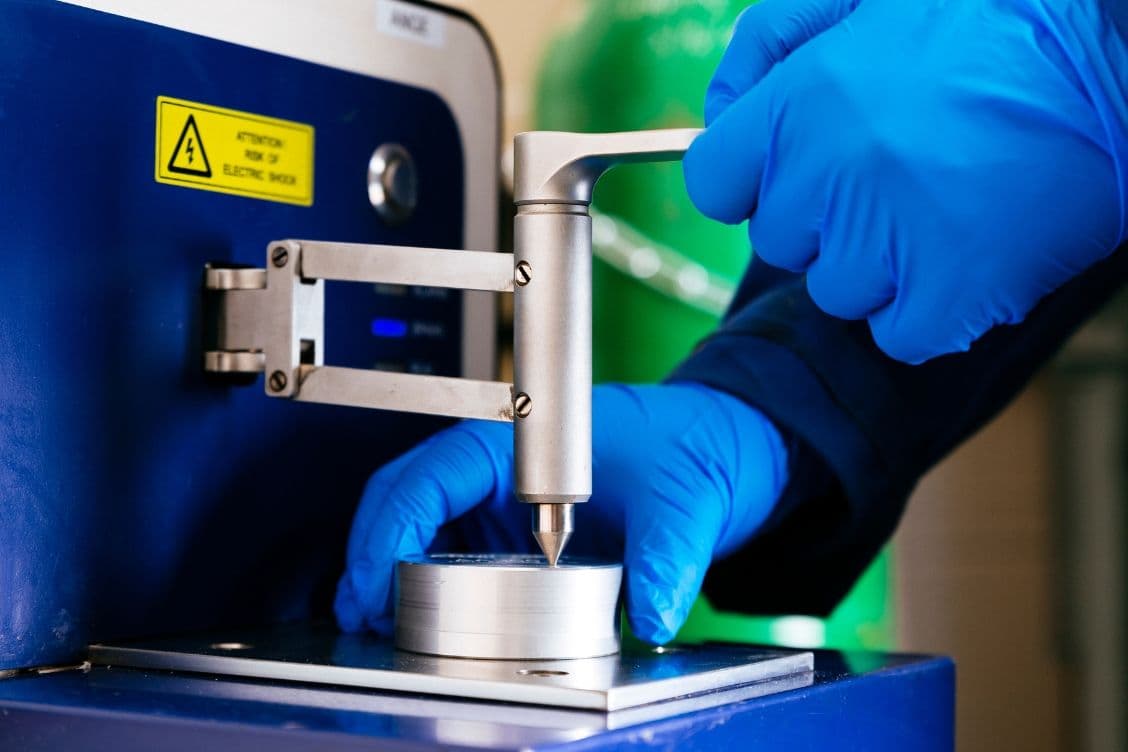

Name: (GC-MS) Gas Chromatography – Mass Spectrometry

Instrument: Agilent 7890 - Agilent 5977 with PAL CTC autosampler

GC is an analytical technique that allows for the separation, identification and quantification of volatile compounds. Combined with mass spectrometry, that detects compounds by their molecular mass. This apparatus allows for the detection of a broad range of volatile and semi-volatile compounds, with high sensitivity and selectivity. GC-MS can be used for a multitude of applications including; environmental samples (water, air), fuels & oils, VOCs, CFCs. Our CTC autosampler provides us versatility of direct sample injection or the use of headspace analysis to provide us a even greater range of analysable compounds.

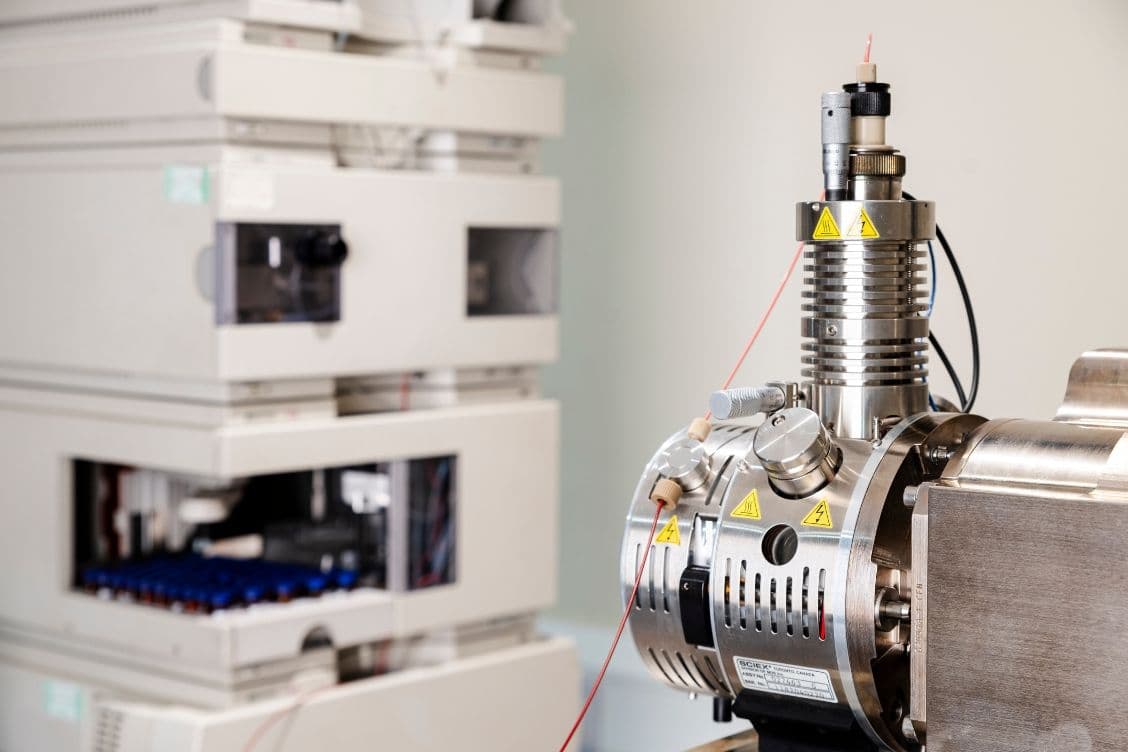

Name: (HPLC-MS/MS) High Performance Liquid Chromatography – Tandem Mass Spectrometry

Instrument: Agilent 1100 – Sciex API-4000

HPLC is an analytical technique that allows for the separation, identification and quantification of samples in a liquid solution. Combined with tandem mass spectrometry, that detects compounds by their molecular mass. This apparatus allows for the detection of a broad range of compounds, with high sensitivity and selectivity. HPLC-MS/MS can be used for a multitude of applications including; environmental samples (water, soil), industrial chemicals, residue analysis.