Description

Fatigue is perhaps, one of the most common causes of failure of engineering metal alloys. The cost of fatigue cracking to the engineering industry is vast due to failures, preventative measures, and replacement of components.

Fatigue occurs when a material is subjected to a fluctuating (cyclic) tensile stress and after a period of time, a small microcrack initiates and then grows progressively through the material until the crack reaches a point where the remaining section of material suddenly fractures. Sources of this cyclic stress may include vibrations in the system, stress cycling, and thermal cycling.

The first article on failure caused by cyclic stress was published in 1837 by Wilhelm Albert. His mine chains failed and so he made what was probably the first machine to simulate fatigue. He then went on to design the first braided steel rope. In 1839, Jean-Victor Poncelet, described metals as getting ‘tired’ during his lectures at a military school in Metz. One of the first disasters reported as a consequence of fatigue was the Versailles train crash in 1842, which killed up to 200 people. It was Braithwaite that finally used the word ‘fatigue’ in 1854 when reporting on common service fatigue failures.

There are various forms of fatigue, such as rolling contact fatigue, thermal fatigue, creep and impact fatigue, and corrosion fatigue, but this paper discusses the most common form, high cycle fatigue. The high cycle fatigue regime occurs, as the title suggests, at high cycles, but relatively low stress, rather than the converse, of low cycle and high stress (discussed in another white paper). With this regime, the stress is predominantly below the yield strength of the material and any strains or deformation are in the elastic zone.

Mechanism

Fatigue cracking can only occur when stress fluctuates, and this is usually referred to as stress cycles. These stress cycles progressively develop cracks. High cycle fatigue cracks can propagate from any free surface, particularly those in areas of concentrated stress.

To understand fatigue, we need to consider the metal at the atomic scale. A metal is made up of crystals with atoms following defined arrangements in the form of planes, but these planes exhibit faults such as gaps or extra rows. When the metal is subjected to a stress that is nominally below the yield point, i.e. in the elastic range, these defects, termed dislocations can and will cause other dislocations to generate and some to move, resulting in small movements in the planes of atoms. Under some steady state loading conditions, this movement may ultimately reach a point where it stops and the material may be considered to have undergone ‘shakedown’; the material behaves truly elastic, and the material does not initiate cracking or generate further dislocations. However, if loading is sufficient but still below the yield point, plastic (permanent deformation) shakedown may continue.

The conventional view of crack initiation is that at a free surface small extrusions and intrusions develop due to the movement (dislocation pile up) of the atoms and that these intrusions develop into small cracks. However, cracking from such intrusions has not been directly observed. John Campbell FIMMM, in a recent article[1] has suggested that this conventional model does not explain the failures observed in service or laboratory tests, and proposes that the introduction of small crack-like defects in the material from the original production of the molten metal, termed ‘bifilms’, is the more likely source for crack initiation, and not just for fatigue, but other failure mechanisms too. These bifilms are caused by turbulence and ‘splashing’ of the surfaces of the molten metal during casting or pouring of the original ingot, on which thin layers such as oxides or other films may exist. These films are folded over on themselves creating microscopic areas of two films in contact (hence bifilms) which prevent mixing and fusion of the molten metal surfaces.

Even with the existence of bifilms, the role of dislocation movement still has an effect on fatigue initiation and propagation. Fatigue cracking of metals is affected by the ordering of the atoms within the grains or crystals. The form of this ordering is known as the lattice structure, and it varies between different metals. Austenitic stainless steels and brasses for example have a lattice structure that is face centred cubic (fcc), whereas carbon steels and ferritic stainless steels have a lattice that is body centred cubic (bcc). Others, like magnesium and zinc are hexagonal close packed (hcp). Metals that are fcc or hcp have the potential to propagate fatigue cracks at any stress variation. However, a bcc lattice has a lesser potential for dislocation movement and as a consequence, bcc materials will not propagate fatigue if the stress is below a certain value, known as the fatigue limit. By designing components that are made of a material with a bcc structure, and which operate below the fatigue limit, it is possible to prevent fatigue completely. For materials that do not exhibit a fatigue limit, the fatigue life of the component needs to be carefully calculated to ensure it is replaced at a predetermined interval, before cracks have initiated. The graph below demonstrates the difference in fatigue properties of a steel and aluminium alloy.

It is interesting to note that although steels exhibit a fatigue limit, in the presence of corrosion this limit is eliminated, and the material behaves much like a fcc material.

Appearance and Examples

When fatigue cracks propagate through a material, the crack front advances in a staged manner with the crack advancing for each damaging stress cycle. Examination of the fracture face at microscopic levels can reveal a series of bands, or striations, that show this propagation. At lower magnifications, or by the unaided eye, the fracture surfaces may also exhibit similar curved or stepped features caused by major changes in crack propagation rates due to variations in loading, exposure to corrodents, or ingression of contamination into the cracks, and these macro-effects are termed ‘beach marks’. The result is a crack that when examined, can help to locate the point or general location of crack initiation.

Occasionally, beach marks may not be present or are difficult to identify and particularly so when the stress cycles are constant or when cracking is in a relatively inert atmosphere. Due to the generally coarse grain structure in castings, fatigue fractures may also be relatively devoid of evidence of progressive crack growth such as changes in fractographic features and may appear as brittle overload fractures. Variations in the extent of corrosion or ingress of contamination may then be the only evidence to indicate failure was progressive, and by fatigue crack growth.

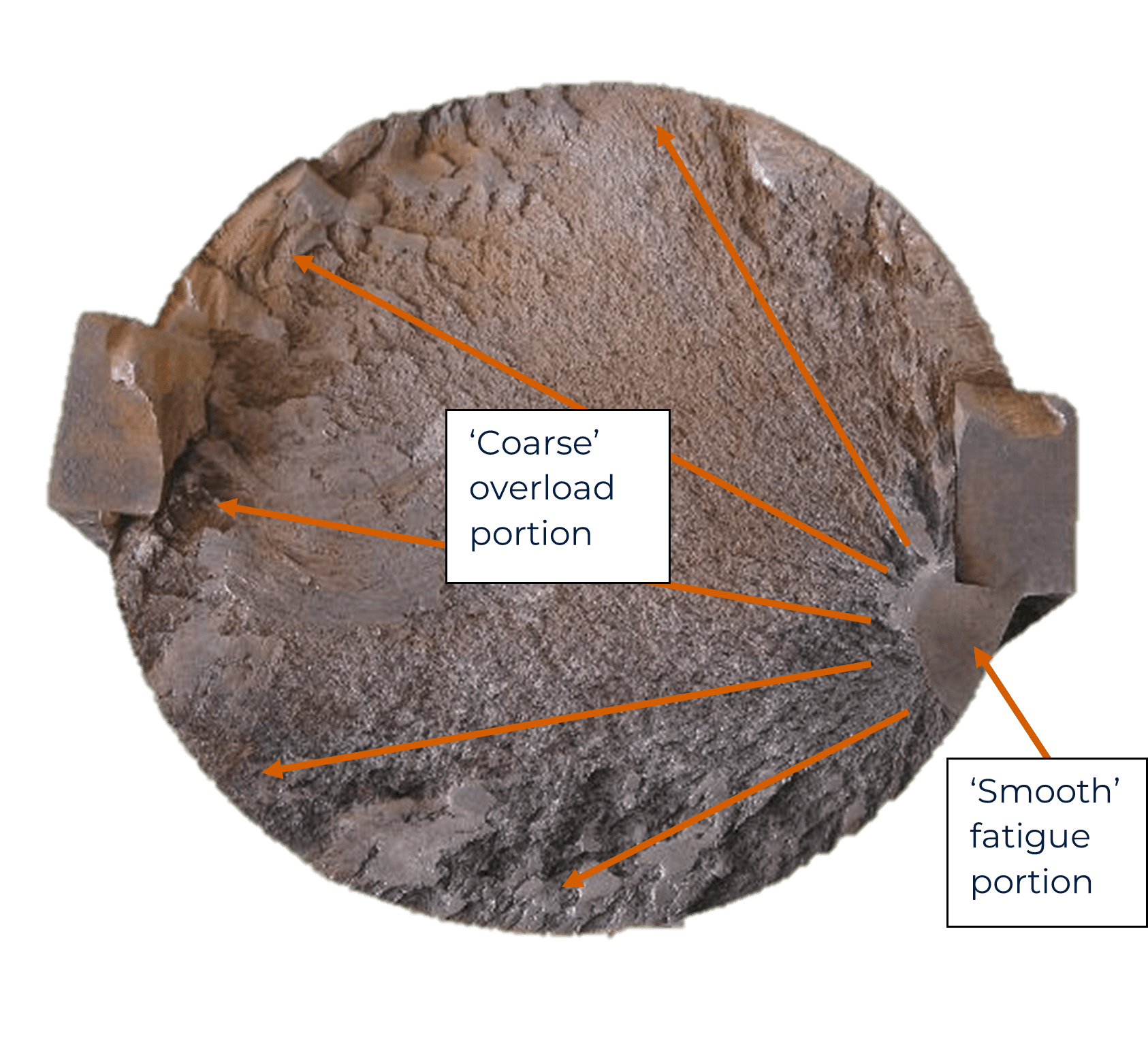

When a component fails by fatigue cracking, the fatigue portion of the overall crack will not cover 100% of the entire section. As the crack propagates, which reduces the remaining cross-sectional area, stress will increase, given that stress is load per area. This stress will gradually increase until the resulting sectional stress either causes yielding, or overload fracture. A qualitative assessment of the nominal loading and hence, sectional stress, can then be obtained by the relative areas of fatigue and overload. The image below shows a small fatigue crack that initiated at the edge of a keyway in a shaft. The fatigue fracture only propagated a small distance beyond the base of the keyway before the rapid brittle overload fracture of the majority of the shaft section. This indicated that the nominal sectional stress was high. It can also be seen that the fatigue portion is particularly smooth with minimal evidence of beach marks indicating a low cyclic stress and high cycles.

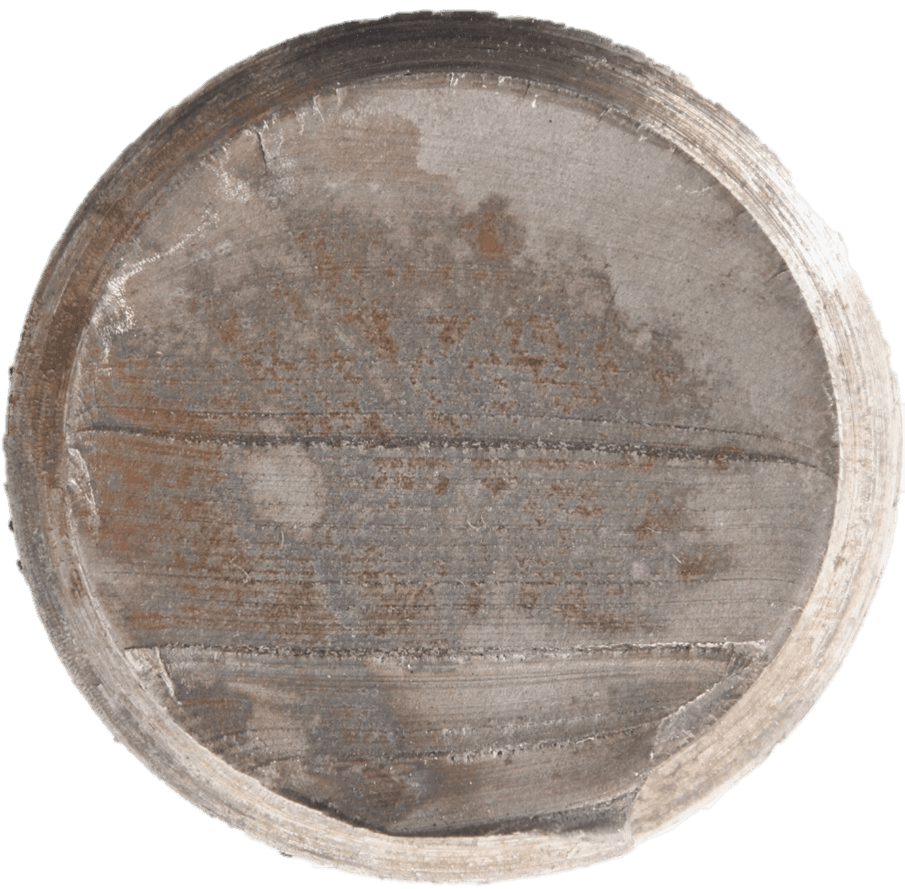

Conversely, the image below shows the fatigue fracture of another shaft, but threaded in this case. Fatigue crack progression is clearly identified with (horizontal) linear steps, or beach marks. Two of these marks are coarse, and these indicated areas of high loading resulting in short bursts of overload fracture. The crack propagated from the top of the image and continued to the lower edge of the image with an almost indistinguishable area of final overload fracture and so this showed that the nominal sectional stress was very low; the shaft was still operating with a minimal ligament of material remaining. It may just be observed that the beach marks at the surface are curved downward in the image. This shows that crack propagation was advancing at the surface (the thread root), ahead of that in the main section of the shaft, and is a feature that indicated a high stress concentration, which may be expected with a threaded shaft; the thread roots providing the stress concentration.

So, beach marks and general fracture features can provide some qualitative information of loading, and this may offer some information on the loading history of the component. Unfortunately, most engineering components do not exhibit a well-defined loading history, and particularly when the service environment is variable. However, some equipment may be exposed to known service cycles, in which case, some correlations between fracture features and service history can be made. For example, the fracture surface on the railway wheel that caused the derailment of a passenger train at Sandy, Bedfordshire, in 1998, exhibited an undulating ‘zig-zag’ topography with definite changes in the length of each fracture facet. Investigation of the relative sizes of these facet features showed a correlation with the journey history of the train which was well-documented; the zig-zag form corresponded to the train travelling north, and then south with the lengths of the facets relating to journey lengths in each direction e.g. London-Leeds-London-Glasgow-London etc. It was then possible to identify how big the crack was at any given date which was crucial in a subsequent court case.

Laboratory-based fatigue tests are often carried out in a controlled environment (i.e. in the absence of corrosion or contamination) and with constant stress amplitudes. Fracture faces may then be relatively devoid of features from which to assess crack growth rates. In-situ non-destructive tests may be carried out to monitor crack growth rates, such as the use of ultrasonic testing. Alternatively, the stress amplitude may be deliberately changed at set periods to generate small step features on the fracture face. This then enables the progression history of the crack to be investigated on completion of the test, and the fracture face is studied.

Avoidance

A key factor in avoiding fatigue failures is in its awareness. Despite the years of work done to understand fatigue failures, components still continue to fail by this mechanism. This may be due to factors such as a poor appreciation of fatigue at the design stage, changes in use to produce damaging stress cycles, use of materials of lower quality (e.g. a ‘cheaper’ alternative), damage induced during service from which fatigue can initiate, poor quality control at manufacture, increased loading from other service problems that cause secondary failures by fatigue e.g. poor balancing of shafts, vibrations, or by the effects of corrosion.

At the design stage, calculations can be carried out but the fatigue loading data, sometimes called the design load case, is crucial. Ideally, known service strains, and hence stress, can be measured from in-service tests, but this can be costly or not possible in the case of new designs. In this case, theoretical load cases may be calculated, and these may not always be accurate. With respect to railway axles, some of the most damaging stress cycles can be when the railway vehicles are moving at low speed in and out of depots, due to the tight curves often inherent at these locations, and not during operation on the main network.

A component may have given good service in a particular environment, but if placed in an outwardly similar operational environment, actual service stresses may be different, and potentially increased to damaging cycles, leading to fatigue failure where none has been seen before. It is then not always possible to predict fatigue failure unless full design reviews are undertaken when decisions are made to use equipment or components in other applications, with due consideration given to fatigue.

There is always pressure on designers and manufacturers to reduce costs and an obvious pressure is on the supply of the raw materials or components. Materials will generally be supplied to meet certain standards, grades, or other similar criteria. These criteria will usually be in the form of specific properties within defined boundaries, with cheaper alternatives being supplied at the ‘lower’ end of these boundaries, which outwardly meet the ‘grade’. Designers would usually use lower end properties for calculations to account for this variability, but unless there is a clear understanding of what properties matter for a component, decisions could be made purely on the basis of cost, introducing material or components inadvertently with reduced properties, leading to failures e.g. a component’s function may outwardly be the same as another, but poorer materials and construction, that do not affect its operation, could lead to its premature fatigue failure, for example, by increased inclusions (defects) or a generally weaker material. In this case, consider an electronic component. Choices of component may be available ranging from expensive to cheap that assumingly reflect the quality of construction and use of materials. Outwardly, the electronic performance of the components may be the same, such that they may all conform to a standard and so would appear to all be suitable for the application. However, if the component is installed in an environment where there are vibrations, or increased corrosivity, the cheaper components, through the use of say lower grade materials or less robust methods of construction, may then be subject to premature failure. This of course assumes that expensive materials and components are always better performing, which is not always correct.

It is not uncommon to see components not manufactured to the drawing requirements, and from which fatigue failures have initiated. This is particularly so with seemingly minor things, such as chamfering of holes, and radii at the roots of changes in section. The shape and geometry of these features are usually stipulated on the drawing, but are not always given the appropriate level of attention. The root at the change in section on a shaft could exhibit a form, or surface finish from the use of damaged, or blunt tooling, resulting in sharp corners, significantly increasing the stress at that point and hence likelihood for fatigue crack initiation. Grinding marks may also be orientated perpendicular to the principle stress direction, again causing stress concentrations and fatigue failure; such marks, orientated parallel to the stress direction would be a significant improvement.

There are then may factors to consider when trying to avoid fatigue failures, and unfortunately, it is certain that fatigue failures will continue to occur.